Press-Fit Connectors Attach Without Solder, 2015-05-04, Assembly Magazine

Por um escritor misterioso

Descrição

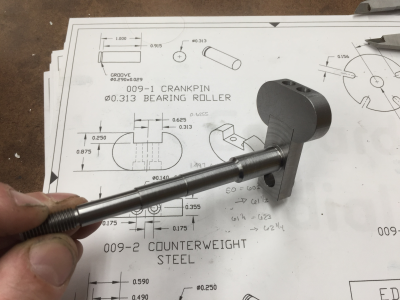

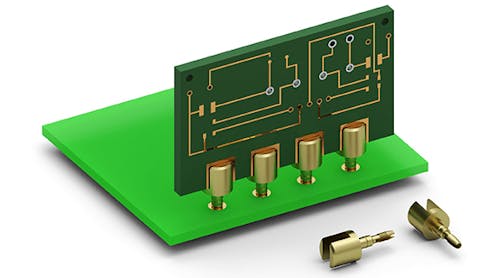

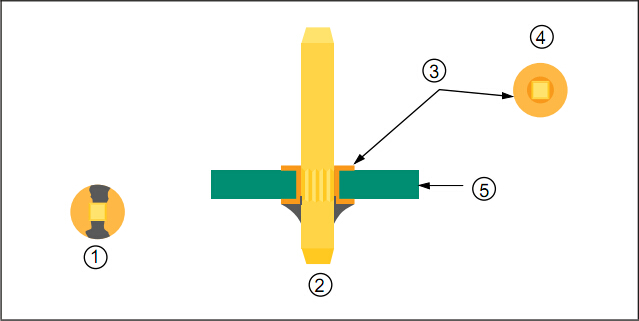

A common misconception about manufacturing (especially among the general public) is that it’s void of innovation. The fact is, new assembly technologies are constantly being developed and introduced to the marketplace. Sometimes, however, an innovation must be modified to become mainstream. Such is the case for printed circuit board (PCB) assembly. From the early 1940s to the early 1990s, nearly all PCB components were attached with one of three methods: point-to-point soldering, wave soldering or reflow soldering. Few components were assembled using press-fit technology. Developed . . .

Manufacturers increasingly rely on press-fit pins and connectors to quickly assemble simple and complex PCBs.

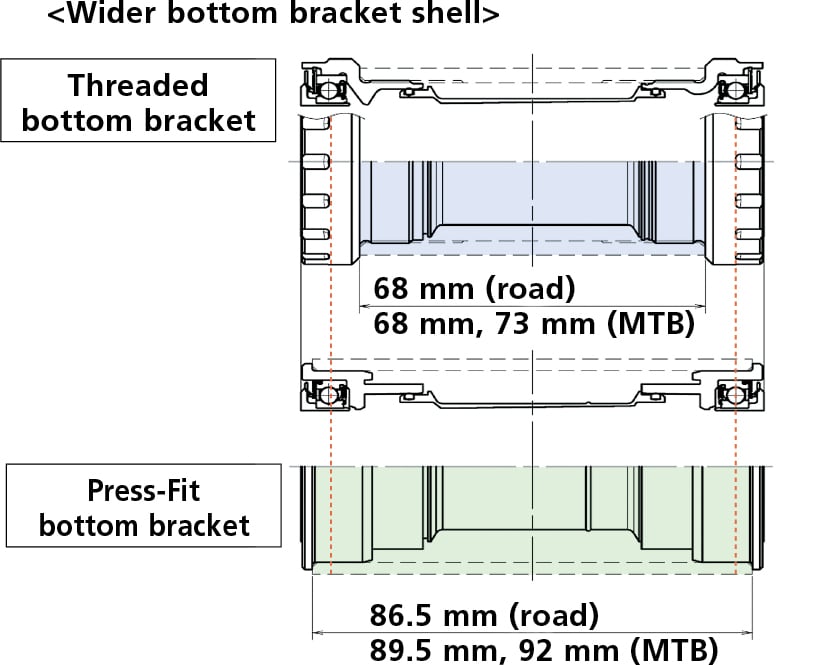

Wave Solder vs. Press Fit vs. SMT

Continued From Part-3: The Patent Office Journal No. 50/2021 Dated 10/12/2021 61585, PDF, Glossary Of Patent Law Terms

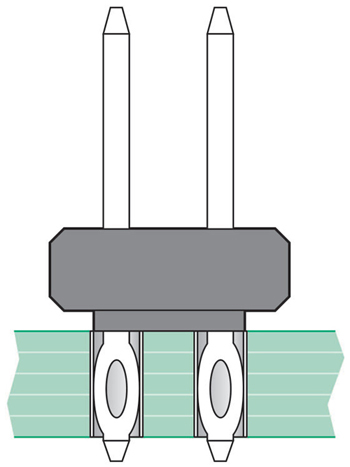

Solderless Press-Fit or Wire Termination/Board Edge Mount

Press Fit Design and Assembly — Worthington Assembly Inc.

PDF) The Maker Movement and Urban Economic Development

thumb_i.png

EEC 136 - Installing Press Fit connectors

Uncategorized – martin hall

Design HMI Flexible Hybrid Electronics

Solderless — Press-Fit capacitors multiple benefits to circuit assembly

Acceptability for Electronic Assemblies-connector pins – Smart EMS factory partne

Design HMI Flexible Hybrid Electronics

US11167375B2 - Additive manufacturing processes and additively manufactured products - Google Patents

Press Fit Instructions (English)

de

por adulto (o preço varia de acordo com o tamanho do grupo)